WEBER

Weber for more than three decades has served red meat, pork, poultry and cheese processors from around the globe, with our solutions enabling a strong customer-base on all continents to accomplish maximum efficiency. Our experience and in-house manufacturing of virtually all machine components has allowed Weber - from its headquarters in Germany to virtually anywhere in the world - to be uniquely positioned to create ideal customer- and product-specific applications. Our unmatched ability to work efficiently with all packaging machinery makes Weber a valuable resource to assist in the custom design of your entire production line.

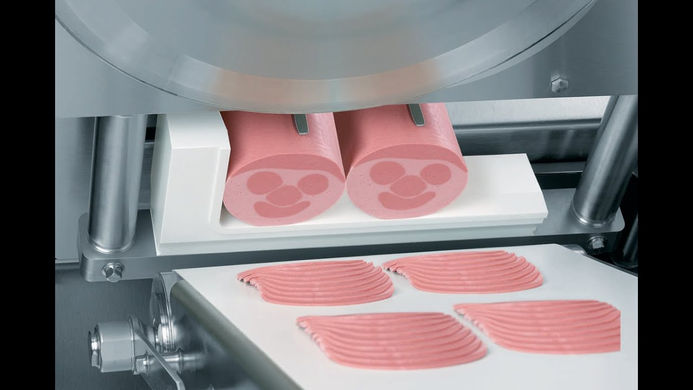

Slicers 305 and 405

SLICER 305

Slicing throat (W x H mm): 250 x 150 max. / 230 x 150 optional

Cutting system : Circular blade

Product length (mm): 800 max

Max. revolutions (rpm) : 400

Slice thickness (mm) : 0.5 to 50

SLICER 405

Machine dimensions (L x H x W in mm) : 3340 x 2410 x 1485

Blade speeds (rpm) : max. 600

Slicing throat (w x h mm) : 120/135/150 (fixed) x 330 (adjustable) or 120 to 165 automatically adjustable

Product length (mm) : 1200

Cutting system : Circular blade

Cutting thickness (mm) : 0.1 – 50

Pick Robot

The Weber PickRobot stands for the uncompromising automation of slicing applications. Specifically adapted to your application area, it can be used flexibly for all insertion tasks and is available in five different executions: SmartPicker, single, double, triple or quad PickRobot.

As powerful and highly efficient automation components with up to 230 picks per minute, the robots integrate perfectly into your line and ensure maximum performance. In combination with the Weber VMAX thermoforming technology, loading portions into an advancing index is possible, which maximises performance even better than ever before. A unique and open hygienic construction aligned with a IP69 protection class do combine automation and the highest hygiene requirements in the processing of sliced goods.

Advantages

-

Flexible, reduced labor costs, and easy-to-clean

-

Multi-variety and multi-layer packs available for compact spaces (overlapping, 90° rotation, variable portion shapes)

-

Complete filling of the package when portions overlap

-

Virtually eliminates human contact

-

Improves food safety

-

Handles all popular portion shapes and sizes

-

Variable numbers of tracks and layersl

-

Automatic position correction

-

Touch-Screen operable from both sides

-

Gripper with quick-change device

-

Double gripper

-

Infeed in running tray